THE EXPERIENCED LUCID TEAM BRINGS DETERMINATION TO EVERY PROJECT NO MATTER THE SIZE.

WE ARE AT THE CUTTING EDGE OF

LIFE-TRANSFORMING TECHNOLOGIES

Lucid Labs is a technology development company focused on advanced engineering and precision machining within the medical device industry.

For more than 20 years, Lucid Labs has been a trusted partner to Fortune 500 and mid-cap companies, contributing to the development of medical technologies that have collectively generated more than $50B in revenue. Lucid collaborates with clients from early‑stage exploratory phases through full market launches, partnering to bring complex and high‑impact medical devices to life.

With deep expertise across product ideation, product development, and manufacturing, Lucid Labs has played a pivotal role in the creation of numerous patented medical technologies, with additional intellectual property currently in development. All resulting patents and IP are fully owned by the client, ensuring complete control and long‑term strategic value.

ENGINEERING and DEVELOPMENT

Mechanical Engineering

Equipment Engineering

Fixture Design and Development

Mechanical and Electrical Product Design

Proof of Concept

Process Development and Equipment Design

Custom Automation

PCB Design using Altium

3D Animation of product interacting with dynamic human body

Software CAD: SolidWorks, Creo, Altium Designer, Maya, Inventor

Software FEA: SolidWorks FEA, Abaqus

PROTOTYPING

Swiss Machining

CNC Milling / CNC Turning

Nitinol Tooling Development

Nitinol Component Forming

Marketing Models

Proof of Concept

Production Quality Prototypes

Insert Machining for Injection Molding

Metal Forming

Laser Cutting

Water Jet Cutting

Urethane RTV Functional Parts

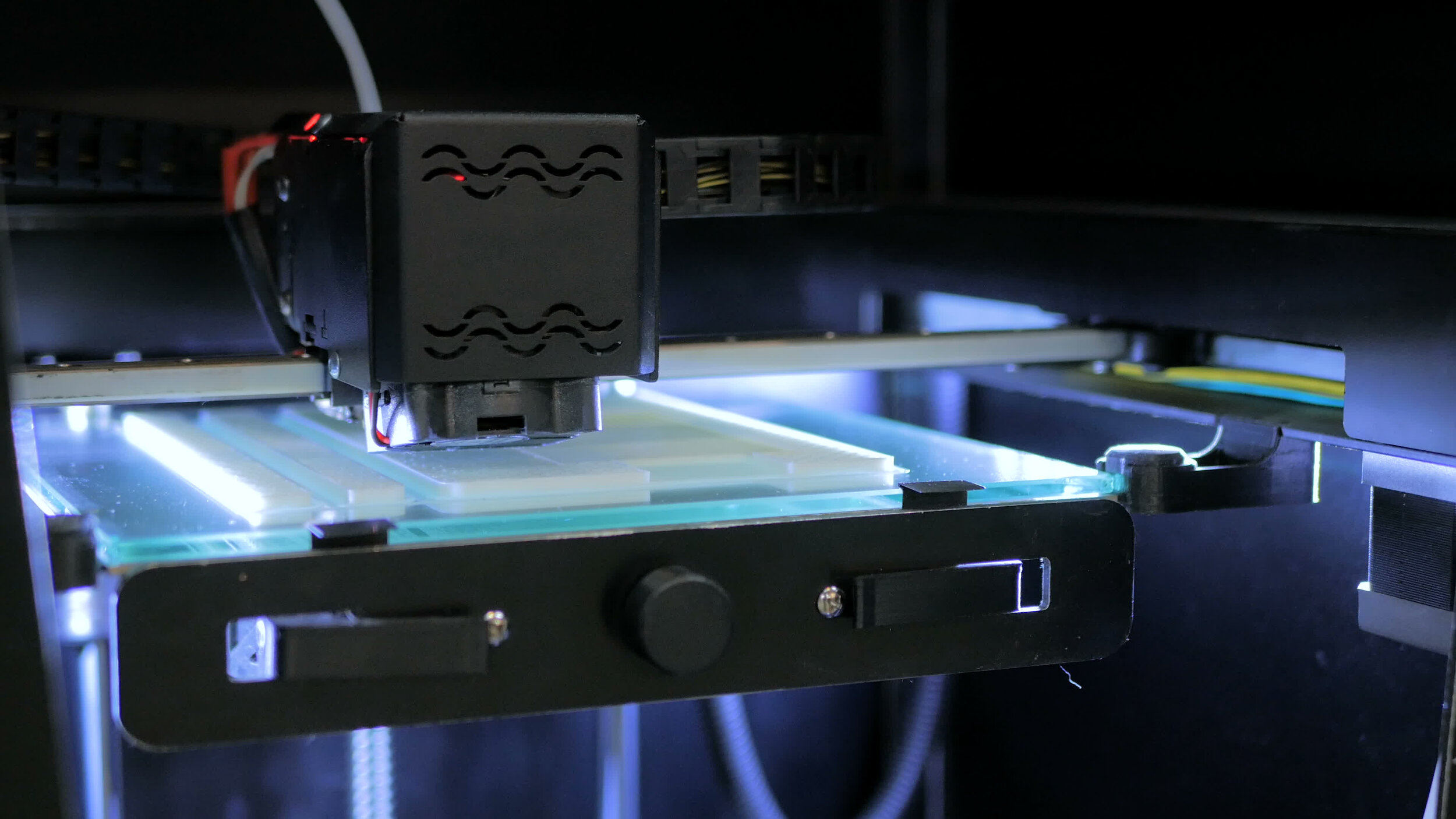

3D Printing / Additive Manufacturing

COMPONENT PRODUCTION and MANUFACTURING

Production Level Fixturing Equipment

Surgical Robotic Component Production

Implantable Components

Component Production for Class I, II, and III Devices

Component Design for Manufacturing Assessment (DFM)

CNC Lathe

Machine Assembly / Secondary Operations

Wire EDM - 0.002" / 0.006" / 0.010" Wire

3, 5, 7, and 9 Axis CNC Machining

EXPERTISE

CONCEPT DEVELOPMENT client visions are clarified into designs

PRODUCT DEFINITION helping establish primary product features

INDUSTRIAL DESIGN forming product aesthetics, ergonomics, usability, and functionality

PROTOTYPING/3D PRINTING delivery of client Proof of Concept

PRODUCT DESIGN client designs are transformed into 3D and digital models

ENGINEERING multi-disciplinary team providing comprehensive innovation

SYSTEM EQUIPMENT ENGINEERING design implementation and installation of production equipment followed by fixture development

MANUFACTURING integration of the product development and process development into production

MANUFACTURING TESTING validation that final product meets design intent

PACKAGING & ASSEMBLY